Quality & Compliance (HACCP)

Build quality checks into your production process—track food safety at every step

What You Can Do

Set up quality checks for each production step

Record measurements during production

Log corrective actions when checks fail

Maintain records for inspectors and auditors

Link quality checks to specific batches

Track who performed each check and when

Ensure critical checks are completed before finishing

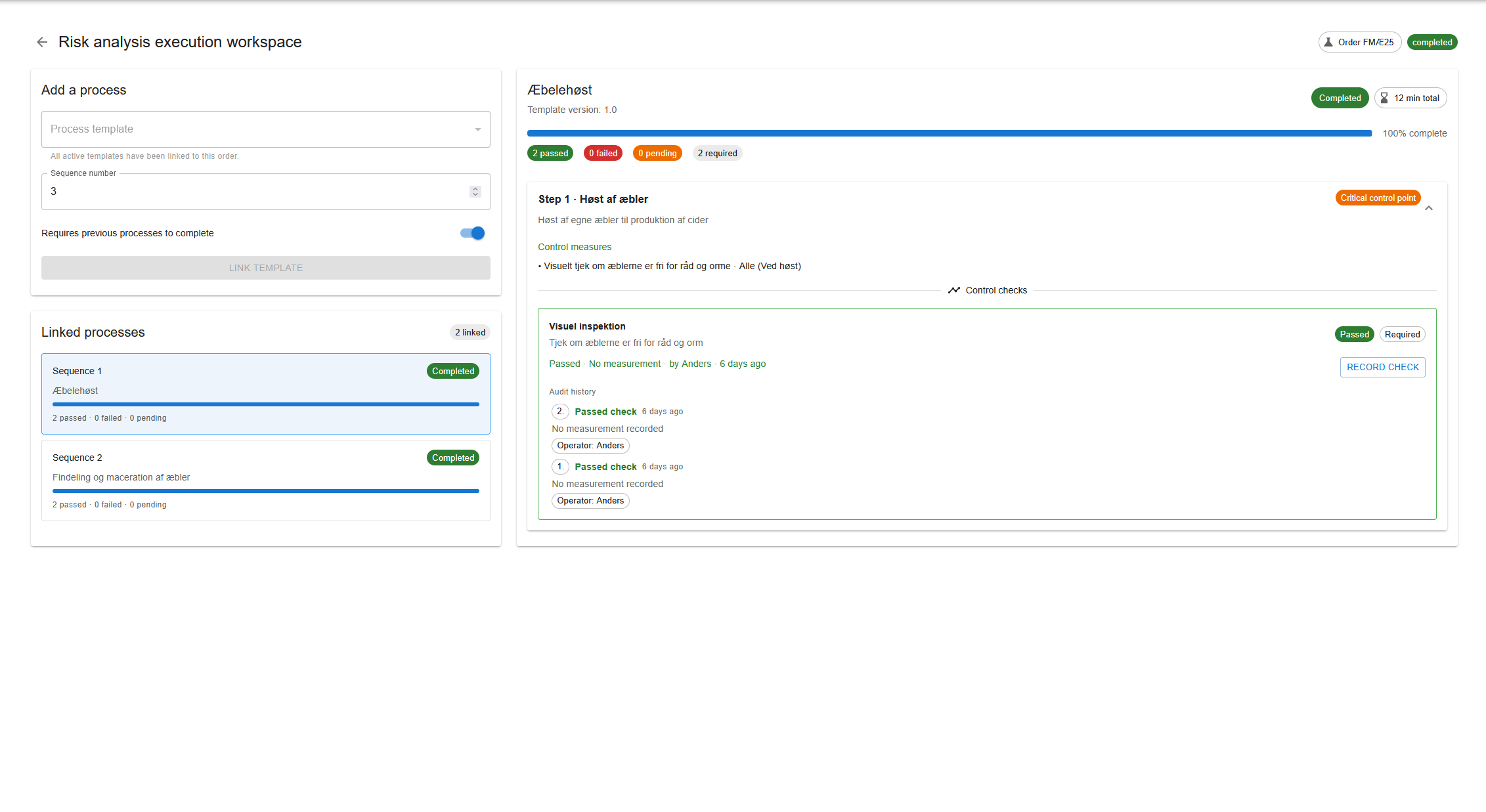

Integrated HACCP Execution During Production

Quality and food safety checks built directly into your production process. Record measurements, log corrective actions, and maintain audit-ready records—no separate paperwork needed.

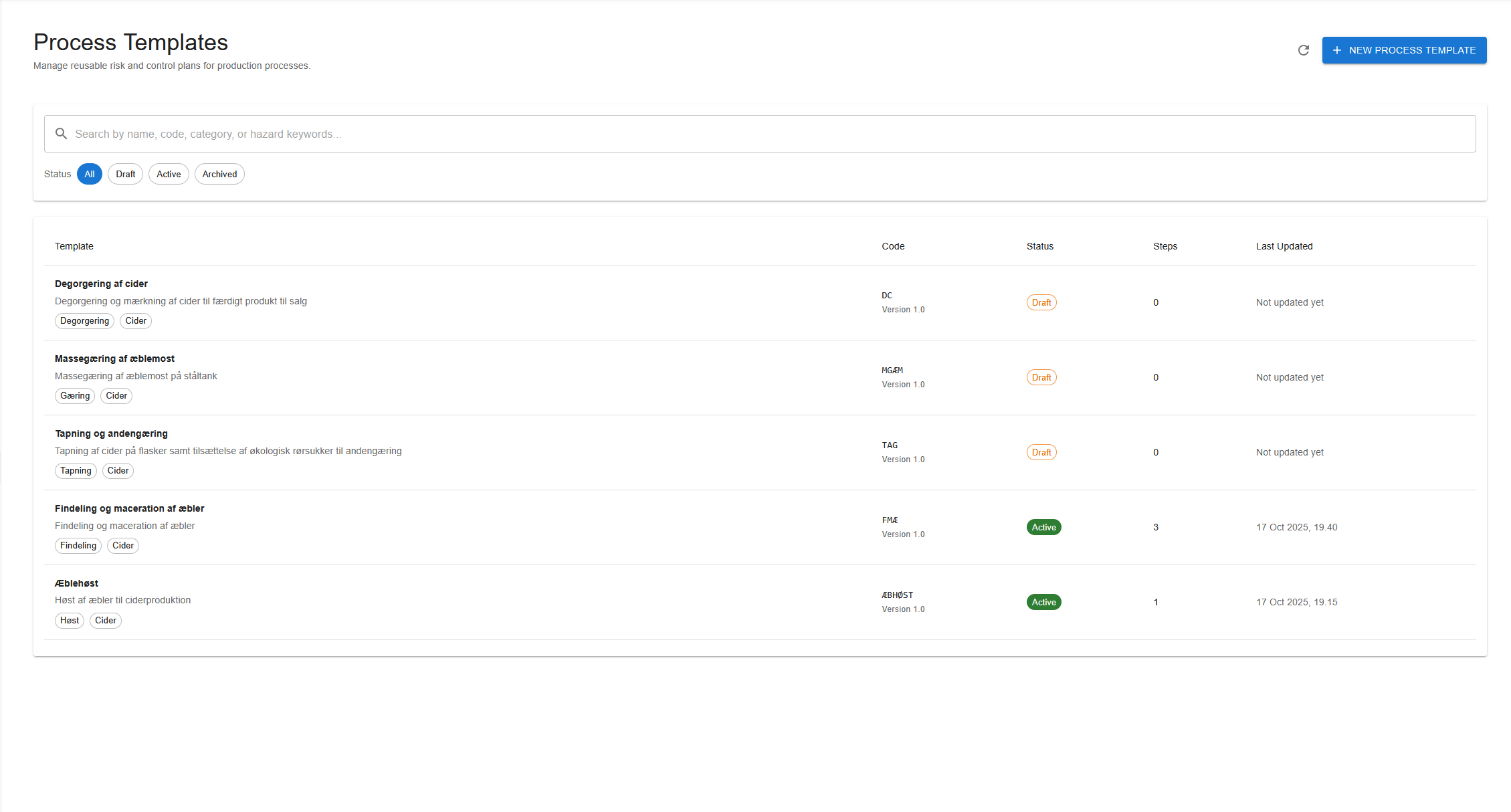

Setting Up Quality Checks

Define which checks your team needs to perform during production. Use our AI assistant to generate complete HACCP templates from a simple description:

- AI generates process templates with CCPs and control checks from plain language

- Create templates for recurring production processes

- List potential hazards for each step (bacteria, contamination, etc.)

- Define critical control points that must be checked

- Set measurement limits (temperature ranges, pH levels, etc.)

- Mark which checks are mandatory before completion

During Production

Execute quality checks as part of your production workflow:

- See all required checks listed in the production order

- Record measurements as you work (temperatures, times, visual checks)

- Mark checks as pass or fail in real-time

- Take photos as evidence of quality checks

- Block production completion until critical checks pass

- Track which operator performed each check

Corrective Actions

Document what you did when checks fail:

- Log corrective actions with operator notes

- Record why a check failed and what was done

- Link actions to specific failed checks

- Maintain complete history of all corrections

- Show corrective actions in audit reports

Audit Trail & Reports

Keep complete records for inspections and compliance:

- View all checks performed for each batch

- See timestamps and operators for every check

- Generate reports linking checks to batches

- Prove food safety compliance to inspectors

- Track patterns in failed checks over time

Start with all modules included

All modules included in every plan. Start your free trial today.